Energy chains

The 6 best energy chain systems for virtually all applications

jhang | 20. January 2022

Are you looking for a suitable energy chain for your application, but having a hard time finding the right product? Then you are exactly at the right place! In this article, we have compiled for you the 6 best energy chain systems with which you can successfully implement 90% of all applications. We evaluated them on the basis of the following criteria:

- Bestsellers and brand awareness

- Technical advantages

- Special functionality

- The long service life of the product

The 6 best energy chain systems for virtually all applications

- The system E2.1 micro – Very small space

- The system E2.1 –The stable all-rounder, easily openable

- The system R2.1 – Protected from dust and dirt

- The system E4.1L –The ideal mix of stability and lightweight

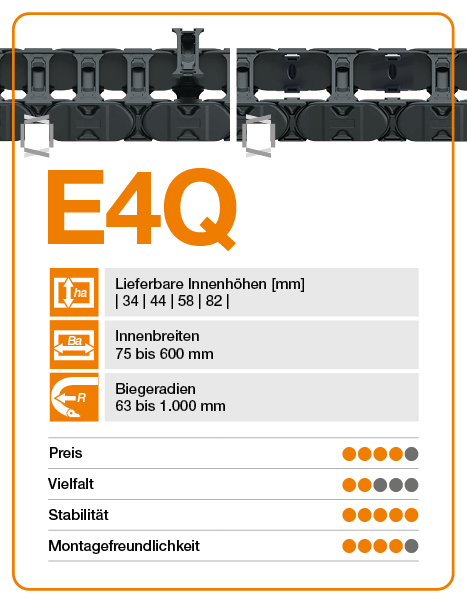

- The system E4Q –Tool-free opening and closing

- The system E4.1 –Robust, quiet and modular

1. The E2.1 micro system for very small spaces

The E2.1 micro system is a very small, one-piece or two-piece energy chain that is lightweight and thus ideal for highly dynamic applications. Compared to igus® types of the same design, the E2.1 micro energy chain also offers a robust stop-dog system for up to 25% greater unsupported length and 100% higher fill weights.

Typical industries and applications: Automatic doors, vehicles, measuring machines and general mechanical engineering

2. The system E2.1 – The stable all-rounder, easily openable

The E2.1 energy chain was first introduced in 2019 and was considered the successor to the E2/000 system, which has proven itself for over 15 years. Compared to the E2/000 system, the E2.1 promises more installation space, easy filling and installation, and a long service life. This makes the E2.1 the best energy chain for the medium load range.

Typical industries and applications: Machine tools, woodworking machines and general mechanical engineering

3. The R2.1 system protects cables from dust and dirt

Are you looking for an energy chain with a tightly sealed design to protect cables from chips? Then we recommend the R2.1 energy tube. It is a cost-effective, strong system with a very tightly sealed design and strong double stop-dogs for high fill weights as well as unsupported lengths. Allowable temperature is from -40°C to +120°C and for hot swarf up to +850°C, available upon request.

Typical industries and applications: In all areas with dirt and swarf, machine tools, woodworking machines, textile machines and general mechanical engineering

4. The system E4.1L – The ideal mix of strength and lightweight

With the compact design and perfectly matched elements, the energy chain E4.1L brings the highest efficiency at a cost-effective price. An easily accessible interior, improved crossbars and separators and the new honeycomb strain relief system result in an 80% faster installation. A cable-friendly interior ensures a long service life for the cables. The E4.1L reduces downtime and the installation and maintenance time whilst saving time and money in operation and acquisition.

Typical industries and applications:Machine tools and general mechanical engineering

5. The E4Q system – Tool-free opening and closing of an energy chain

The E4Q energy chain is the latest generation of installation-friendly energy chains and has been developed to provide the best possible solution for unsupported and long travels. This energy chain can be opened and closed easily and quickly by hand – i.e. 100% tool-free, thus 40% faster filling compared to the E4.1 system. In addition, 10% less weight with high stability, means 10% less energy consumption in production.

Typical industries and applications: Machine tools, crane systems, automation systems and general mechanical engineering

6. The system E4.1 – Robust, quiet and modular

With the E4.1 energy chain, you can further increase the service life of your application and thereby bring the Cost down. The E4.1 has an undercut design for ideal lateral stability, high push/pull force on long travels and long unsupported length, and a noise-dampening brake.

Typical industries and applications:Cranes, indoor cranes, composting plants, wastewater treatment plants, machine tools, general mechanical engineering, conveyor technology, refrigeration, construction machinery, wood processing and robotics as well as handling

When do I use which energy chain?

- If you have an application with limited space, the inner height is between 10.1 to 14.4mm and the fill weight is between 0.7 to 1.25kg/m, then the E2.1 micro system is the right choice.

- For more interior space with inner heights 26, 38 and 48mm and medium load range 5 to 14kg/m we recommend system E2.1.

- If you need an energy chain for protection against swarf, then we recommend the R2.1 system.

- If you want to open and close the energy chains completely without tools and save 40% installation time, then the E4Q system is the right energy chain for you.

- With the E4.1 system, you can implement applications with inner heights between 21 and 350mm and a fill weight between 4 and 600mm.

- With the system E4.1L, you will get the best mix of strength and lightweight specification with inner heights between 31 to 64mm and a fill weight between 7 to 40kg/m.

With these 6 best energy chain systems you can implement 90% of all applications. In addition, you can avail of our online energy chains configuration (e-chain expert). After a few entries, you will be shown the correct energy chain for your application.

Reference:

The 6 best energy chain systems for virtually all applications